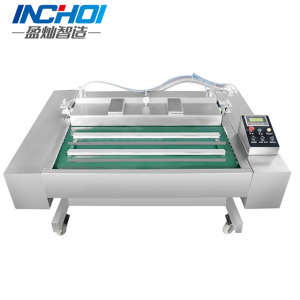

DLZ-420/520 Computer tsis siv neeg nruam stretch thermoforming lub tshuab nqus tsev ntim tshuab

Video

Technical Parameters:

| Qauv | Upper zaj duab xis dav | Hauv qabzaj duab xis dav | Nqus degree | Compressed cua | fais fab mov | zog | Qhov hnyav tag nrho | Qhov ntev |

| TSW-420 | 397mm ua | 424mm ua | ≤ 200 hli | ≥0.6MPa | 380V 50HZ ib | 14 kWm | 1800kg ib | 6600 × 1100 × 1960mm |

| TSW-520 | 497mm ua | 524mm ua | ≤ 200 hli | ≥0.6MPa | 380V 50HZ ib | 16 kWm | 2100 kg ib | 7600 × 1200 × 1960 hli |

Product Detail:

1.Drive system

2.Nyob rau hauv zaj duab xis pre-tensioning positioning ntaus ntawv

3. Lifting system

4.Cross cutter ntaus ntawv

5.Servo coding system

6.Upper Zaj duab xis tsim khoom

7. Pov tseg rov siv dua

8.Electrical txee los ua ke daim duab

Daim ntawv thov:

Cov khoom siv yog tsim rau: steak, grilled sausage, nqaij sausage, crispy sausage, pickled qaib taw, quail qe, qhuav tofu, ntses khoom, nqaij nyuj khoom, yaj cov khoom, av sauce, qhuav txiv hmab txiv ntoo, cheese, electronics Cheebtsam, khoom siv hlau thiab lwm yam khoom uas xav tau lub tshuab nqus tsev ntim khoom.

304 Stainless hlau ncej qauv

1. Cov qauv muaj lub zog siab thiab corrosion kuj.Cov ntsia hlau qhov nyob rau hauv txhua txoj hauj lwm tsau yog ua tiav los ntawm high-precision laser nyob rau hauv ib lub sij hawm los xyuas kom meej qhov tseeb ntawm kev sib dhos thiab ua kom tag nrho lub tshuab khiav smoothly.

2. Kev nthuav dav ntxiv, thaum daim ntawv ntim yuav tsum tau hloov kho dua tshiab, cov khoom tseem ceeb tuaj yeem muab ntxiv rau txhua lub sijhawm raws li kev ntim khoom.

Plaub-axis txuas lifting ntaus ntawv

1. Cov khoom nqa nqa yog ua los ntawm 6061 aviation aluminium alloy, uas ua rau kom muaj kev ruaj ntseg thiab lub zog ntawm cov khoom.Cov zawv zawg qhov chaw txais yuav cov khoom siv siab hnav-tiv taus linear bearings, uas yog qhov tseeb hauv qhov chaw thiab ruaj khov hauv kev ua haujlwm.Lub lifting qhov siab tuaj yeem hloov kho arbitrarily raws li lub thickness ntawm cov khoom ntim.Yog tsis hloov qhov kev khiav ceev, lub lifting nrug yog shortened los txhim kho lub ntim ceev ntawm tag nrho cov tshuab.

2. Cov khoom yog inlaid nrog graphite tooj liab lub tes tsho kom ntxiv lubrication, txo puas thiab ncua lub neej kev pab cuam.Tsis tas li ntawd, lub tes tsho graphite tooj liab yog qhov tsis tshua muaj siab-resistant, uas ua kom lub sealing ntawm lub molding chamber thiab lub tshuab nqus tsev chamber.

Electronic magnetic pre-tightening device

1. Siv electromagnetic nres, tus nres yog ruaj khov thiab lub zog yog txawm, tsis txhob muaj qhov tshwm sim ntawm wrinkling thiab curling ntawm cov khoom ntim.

2. Cov duab digital qhia tau tias lub zog nruj yog adjustable.Tus yuam sij tuaj yeem hloov kho yooj yim thiab intuitively raws li lub thickness, yooj thiab softness ntawm lub ntim zaj duab xis kom ua tiav cov nyhuv ntim zoo tshaj plaws.

Hluav taws xob System

1. Cov kev tswj xyuas ntse tau txais lub npe German Siemens uniformly, thiab cov ntsiab lus tswj tau teb thiab koom tes.Qhov kub, lub sij hawm, thiab lub tshuab nqus tsev siab ntawm txhua qhov yog tso tawm rau ntawm lub computer screen, thiab nws muaj nws tus kheej kev ua txhaum kev ua haujlwm.

2. Txais German Siemens siab inertia servo lub cev muaj zog thiab tus neeg tsav tsheb, cov saw saw yog qhov tseeb thiab khiav ceev.

Intelligent operating system

1. Kov npo ua haujlwm, tsis siv neeg tswj kev tswj hwm, cov duab kos duab ntawm tag nrho cov xwm txheej khiav, tsis siv neeg tshawb pom qhov ua rau tsis ua haujlwm, yooj yim rau kev khiav lag luam thiab tswj cov khoom siv.

2. Lub vijtsam ua haujlwm ntse thiab tib neeg ua haujlwm yooj yim dua thiab pom tseeb dua.Txhua qhov ntsuas tuaj yeem hloov kho kom haum raws li cov khoom sib txawv, thiab cov txheej txheem sib txawv ntawm cov khoom tuaj yeem khaws cia.Kev hu ib-nias txuag lub sijhawm thiab kev siv zog.

Kev tiv thaiv kev nyab xeeb

1. Txhua qhov chaw sib kis;qhov chaw nrog kub;txiav thiab txav qhov chaw yog nruab nrog cov cuab yeej tiv thaiv, thiab cov khoom sib nqus sib nqus tau teeb tsa.Thaum cov cuab yeej tiv thaiv tsis nyob hauv qhov chaw lossis cov khoom siv tiv thaiv lub tshuab qub tsis nyob hauv qhov chaw, lub tshuab yuav nres tam sim ntawd.

2. Cov cuab yeej siv nws tus kheej yog nruab nrog cov hloov pauv thaum muaj xwm ceev nyob rau hauv ntau txoj haujlwm, kom nres lub tshuab hauv lub sijhawm thaum muaj xwm txheej tshwm sim.

3. Nws yog txwv tsis pub ncav tes, taw, caj npab thiab lwm qhov chaw nrog lub teeb hloov, thaum nws hnov, nws yuav nres tam sim ntawd.

Khib nyiab zaj duab xis recycling system

1. Cov khoom pov tseg rov ua dua tshiab muaj cov cuab yeej ntse tshawb nrhiav, uas tuaj yeem kho qhov kev khiav hauj lwm ceev raws li qhov ntev ntawm cov yeeb yaj kiab pov tseg.

2. Cov cuab yeej tsis muaj suab nrov, yooj yim los sau cov zaj duab xis, nruab nrog 150W lub zog, kev ua haujlwm tsis ncaj, txuag hluav taws xob.

Kev tsim thiab kub sealing pwm

Tag nrho cov pwm tuaj yeem hloov tau sai, thiab ntau yam pwm tuaj yeem hloov pauv ntawm cov khoom siv los pab txhawb kev ntim khoom ntawm ntau yam khoom.

Multifunctional slitting system

Raws li cov khoom sib txawv, nws tuaj yeem paub txog lub kaum sab xis slitting, yooj yim tearing, dai qhov, serrated slitting, zuag qhia tag nrho xuas nrig ntaus thiab lwm yam kev siv, thiab qhov ceev ntawm cutter hloov yog ceev thiab yooj yim.

Paub meej configuration:

1.German Siemens Computer Programmable Logic Controller (PLC) tswj, muaj peev xwm loj thiab tso tawm.

2. German Siemens 10-nti xim tib neeg-tshuab interface kov npo.

3. 1.5KW German Siemens servo tswj qhov system, high-speed thiab high-precision step-by-step ceev.

4. TYC clamping saw

5. Cov khoom siv hluav taws xob txawv teb chaws (American Bonner xim sensor, Schneider contactor & relay, khawm hloov, hluav taws xob tiv thaiv, Yangming khoom lub xeev relay, Japanese Omron sib thooj hloov, thiab lwm yam).

6. Lub pneumatic feem txais Yadeke Valve Terminal pneumatic system.

7. Lub tshuab nqus tsev tsis muaj kuab paug loj rau ib puag ncig-phooj ywg lub tshuab nqus tsev thermoforming ntim tshuab (Rietschle / Busch, xaiv tau rau cov neeg siv khoom xav tau) tuaj ntawm lub teb chaws Yelemees nrog thawj pob, nrog lub tshuab nqus tsev siab tshaj plaws ntawm 0.1 millibar.

8. Imported photoelectric mus txog qhovtwg system thiab xim zaj duab xis yuav siv tau los xyuas kom meej tias tus qauv txoj hauj lwm yog lawm.

9. Tag nrho lub tshuab txais 304 stainless hlau ncej, uas muaj lub zog siab, muaj zog corrosion kuj thiab tsis yooj yim rau deform.

10. Lub sab sauv thiab sab hauv daim nyias nyias tau txais ib hom tshiab ntawm propelling membrane system.

11. Shaping, sealing thiab lifting txais yuav pneumatic lever ywj siab lifting thiab nws tus kheej-locking system.

12. Precision positioning nyob rau hauv pem hauv ntej, nraub qaum, sab laug thiab txoj cai.

13. Transverse cutter ua hauj lwm ntawm nws tus kheej nrog ib tug cutter thiab central computer tswj.

14. Nruab nrog lub kaum pob pov tseg rov ua dua tshiab.

15. Lub lifting zawv zawg bearing txais yuav lub tes tsho tsis muaj graphite tooj liab.

16. Txhua qhov chaw ntawm kev sib sau, sib khi, kab rov tav riam thiab rab riam ntev yog nruab nrog kev tiv thaiv kev nyab xeeb thiab kev tiv thaiv npog.

17. Cov khoom siv tau nruab nrog kev ceeb toom lossis kev tiv thaiv xws li lub zog poob lossis kev hloov pauv, kev siv hluav taws xob ntau dhau lossis tsis tshua muaj hluav taws xob, kev siv lub sijhawm ua haujlwm lubrication, thiab lwm yam, uas yooj yim rau cov neeg siv khoom siv thiab kho.Tsis siv neeg nres kev tiv thaiv thaum muaj qhov ua tsis tiav thiab tso saib cov ntaub ntawv ntawm qhov yuam kev thiab kev kho mob ntawm qhov tsis ua haujlwm ntawm lub computer.